Lab Tour

The creation of your lens in the Advanced Family Eyecare Center lab begins by inputting the plastic lens prescription into the dedicated computer. The computer selects the appropriate lens blank, which is placed in a prescription tray along with your frames, and they travel together throughout the process.

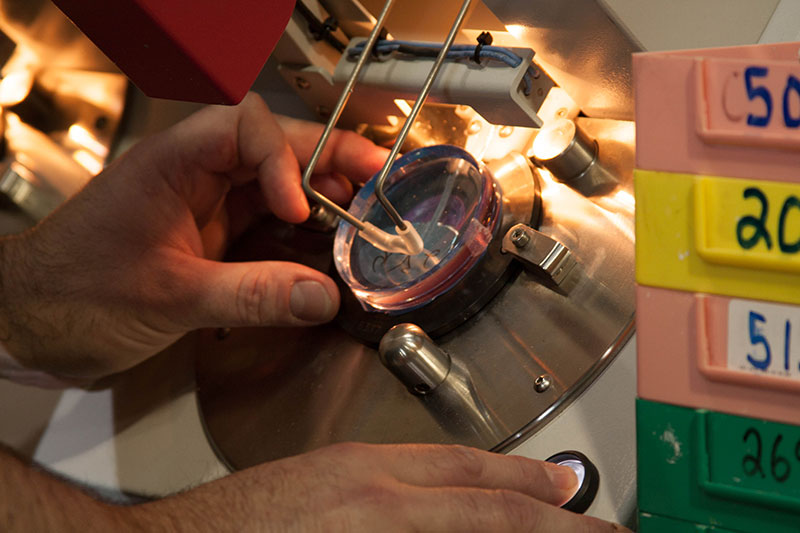

Plastic blanks have different curves pre-ground into their front. With the guidance of the computer, we select the blank that corresponds to the optical prescription required for each lens. The “power” of your prescription must then be ground into the back of the lens. The “lensometer” is used to locate and mark the blanks’ "optical center"—the point that is centered over your pupil. During what is called “blocking,” each blank is protected from scratching and secured in place for the grinding and polishing processes.

The grinding machine is set for the specific optical prescription, and adds the appropriate optical curves into the back of each lens. After this step, the lenses must be polished.

The front of each lens is then polished in a series of four fining operations. Each uses extremely fine sandpaper, until the final step when precision pads are rotated in a circular motion against the lens while a polishing compound consisting of aluminum oxide, water, and polymers flows over them.

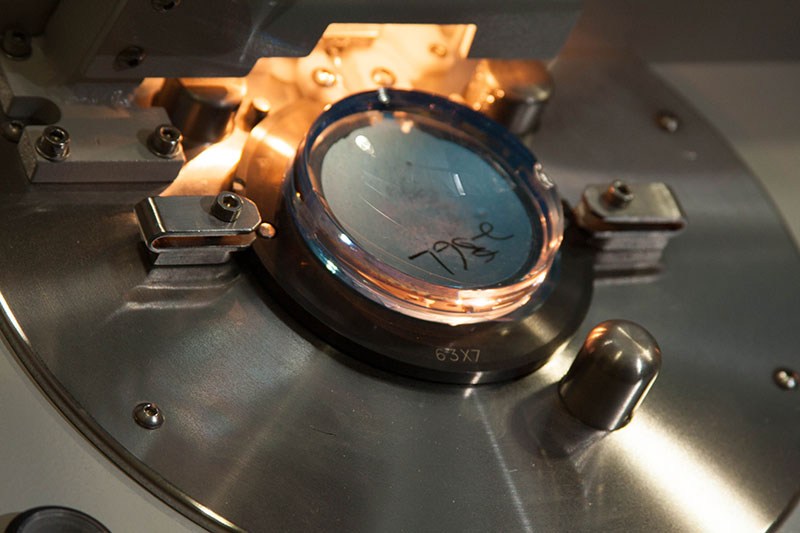

Each lens is marked "L" or "R". The lenses are then again placed in the lensometer to check and mark the optical center and inspect all other curves necessary for the proper optical prescription.